Have you ever been in a situation where you needed your generator, but the pull cord simply refused to cooperate? The good news is that you can solve the problem on your own. You don’t need to be a mechanic or a DIY expert to make your generator pull cord work like new again.

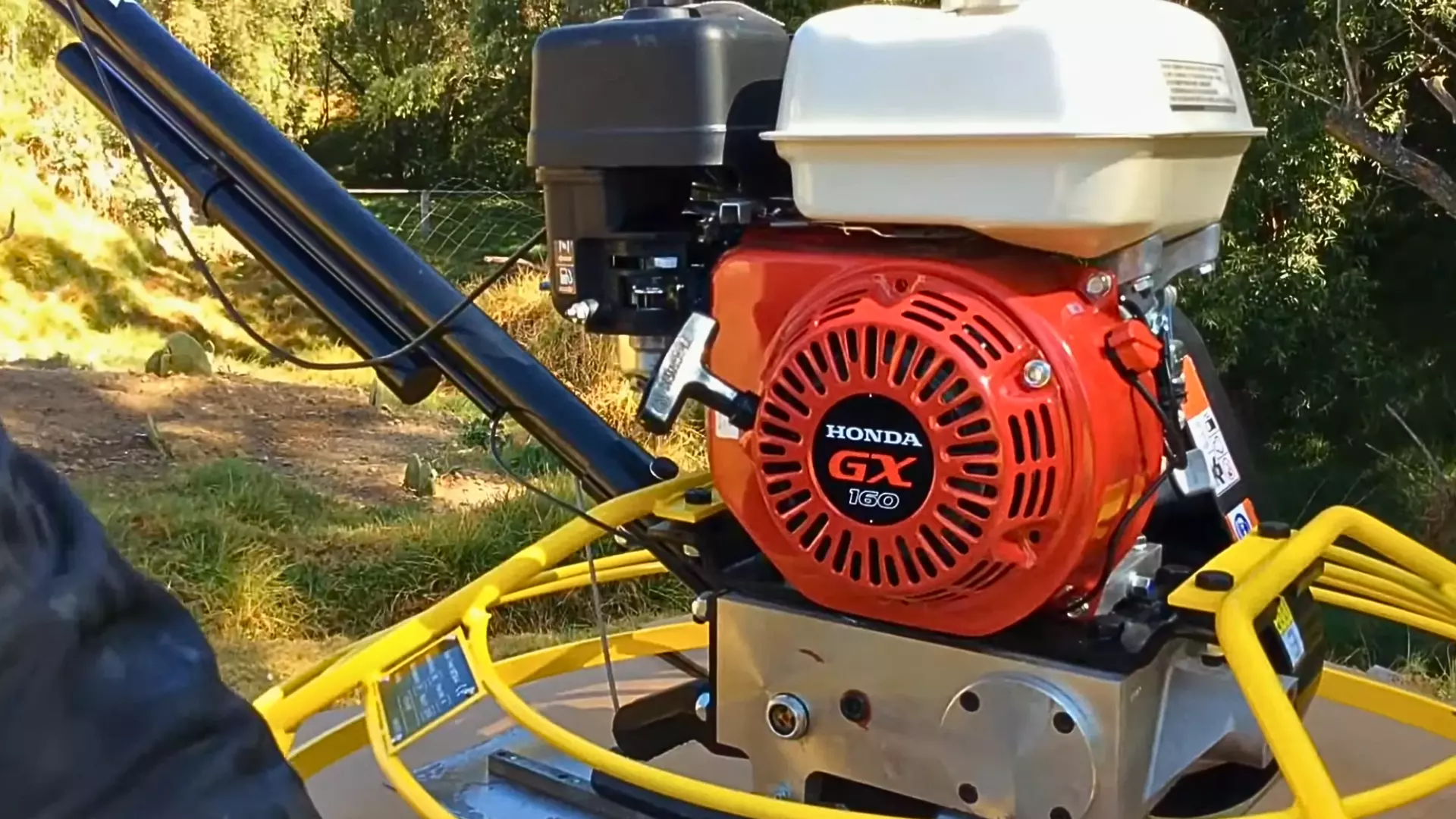

In this easy-to-follow six-step process with a handy guide, we’ll walk you through the steps to your Champion generator pull cord replacement, and other portable open-frame generators like Honda, Generac, Briggs & Stratton, Fairman, Screwfix, and Dewalt generators follow the same process. So, if you’re ready to get your generator back in action without the hassle.

So, How to Fix Generator Pull Cord Replacement

Find the recoil starter and open the recoil cover, then remove the old rope around the pulley, select the right size rope, and replace it with a new rope. The final adjustment is important; last, reattach the recoil starter.

Tools and Materials Needed (List)

- Starter spring (if needed)

- Needle-nose pliers

- Wire cutters

- T-handle socket wrench 10-millimeter, 8-millimeter, both

Before you start fixing a broken recoil rope, ensure the generator is turned off and the spark plug wire is disconnected to prevent accidental starts. Wear safety goggles and work gloves to protect yourself from potential injuries.

Step 1: Access the Recoil Starter

The recoil starter is usually located on the side or top of the engine, tucked away under a cover, which can be made of plastic or metal.

Step 2: Remove the Old Rope

Let’s get rid of that old rope on your generator. After finding the recoil starter cover, held on by three bolds.

Grab a T-handle socket measuring 10 or 8 millimeters, then twist those bolds to free the starter cover.

Once the cover is removed, you’ll see the old rope wound around the recoil starter pulley.

Use a nose plier to yank that old rope out of there and toss it away.

Step 3: Selecting the Replacement Rope

Now that you’ve successfully removed the old pull robe, it’s time to choose the right replacement cord.

The selection process is crucial to ensuring that the new rope is the correct size, diameter, and material for your generator. Here’s how to make the right choice:

Correct Size

If you don’t have the old cord for reference, my recommendation is that the 2.5-fit size is commonly good; otherwise, consult your generator owner’s manual for the recommended length.

Check the Diameter

Examine the diameter of the old cord and select a replacement rope with a similar diameter. Using a rope that’s too thick or too thin can affect how it fits and functions within the pull cord assembly.

Right Material

Replacement pull ropes are typically made from materials like nylon, polyester, or other durable fibers.

Confirm that the material you choose is suitable for the environmental conditions your generator may encounter.

For example, if your generator is often exposed to the elements, opt for a weather-resistant material.

Step 4: Install the New Rope

This time, thread that new rope through the starter assembly. Find the hole where the old rope used to hang out and push the new one through it.

If there are other holes it needs to go through, don’t forget them either. While you’re at it, keep some tension on the rope to avoid any messy tangles or twists.

Once the rope has navigated all the necessary guide holes, tie a knot on the other end. Make sure it’s big enough to stop the rope from slipping back through the assembly hole.

However, if you find that the recoil starter hole is getting worse and the rope is breaking frequently, then you need to change the entire starter assembly.

Step 5: Adjust the Tension (it’s Important)

Tightening Tension: If the cord is too loose, wind it slightly tighter around the recoil starter pulley by turning the pulley clockwise.

Be careful not to over-tighten the cord.

Loosening Tension: If the rope is too tight, carefully unwind it from the starter pulley by turning the pulley counterclockwise (opposite direction of starting).

Remove any excess wraps until the tension is correct. Be cautious not to completely unwind the cord from the pulley. After making adjustments, ensure the pull rope has the right tension—enough to retract the pulley smoothly but not overly tight.

Step 6: Putting the Cover Back

With the new rope perfectly in place and the rope tension adjusted, it’s time to reassemble the starter assembly cover. Carefully place the recoil starter cover back over the assembly, making sure it lines up with the holes in the generator housing.

Secure the cover in place by tightening the three bolts you removed earlier using a T-handle socket wrench. And that’s it. You’re done. Your generator has a brand-new rope, and it is ready to power up when you need it. If your generator needs air filter cleaning, read it.

How to Fix Generator Starter Spring?

Fixing or changing a recoil starter spring can involve a few steps. if needed otherwise, skip this section. But the above mentation process is the same.

Inspect Starter Spring: Check the starter spring for any signs of damage or wear. If the spring is broken or damaged, it will likely need to be replaced. If it’s just come loose, you may be able to reattach it.

Remove Old Spring: Open one bolt located at the center of the recoil pulley using a T-handle socket. If the old starter spring is still attached to the pully, use pliers to carefully disconnect it from the starter mechanism. Take note of how the spring is positioned before removal.

Install New Spring: Take the replacement starter spring and position it in the same way as the old one. Make sure it is securely attached to the appropriate points on the starter mechanism. then reattach the recoil pully and bolt removed earlier.

Some springs may have specific hooks or anchor points, so refer to your generator’s manual if needed. Make sure the new spring is the correct size and type for your generator model.

If you have any difficulty understanding the starter spring changing the whole process, please watch this video.

Finally, reconnect the spark plug wire this time to start the generator and ensure that the new rope and starter spring engage smoothly and the starter functions correctly. If there are any issues, recheck your work and make adjustments as needed.

Common Reasons for Pull Cord Repair

Generator pull rope repair may be necessary for a variety of reasons, as wear and tear, accidents, or mechanical issues can affect the functionality of the cord.

Here are some common reasons for generator pull cord repair:

According to my experience with generator owners,

- Friction and Wear

- Wrong Pulling Technique

- Wrong Rope Length

- Corrosion and Rust

- Stuck or Jammed Cord

- Mechanical Issues

- Old Components

- User Error

Friction and Wear: Over time, the repeated pulling of the rope can cause it to fray, weaken, or break. This is a common reason for repair if your generators see regular use.

Wrong Pulling Technique: Sometimes, users may pull the cord too forcefully or at an awkward angle, leading to kinks or knots in the cord. These can cause it to jam or break.

Wrong Rope Length: If the pull cord is too short or too long for the generator’s specifications or above the recommendation, it can affect its functionality and may need adjustment or replacement.

Corrosion and Rust: Exposure to moisture or humid conditions can lead to corrosion and rust on the components of the pull cord system, affecting its smooth operation.

Stuck or Jammed Cord: Dust, dirt, or debris can accumulate in the cord housing or on the recoil spring, causing the cord to become stuck or jammed when pulled.

Mechanical Issues: Problems with the generator’s recoil starter mechanism, such as a damaged spring or ratchet, can prevent the rope from retracting properly or engaging the engine.

Old Components: As generators age, their pull cord assembly may deteriorate, requiring the replacement of various parts like the handle, cord, or recoil spring.

User Error: Incorrectly reassembling the pull cord recoil starter after maintenance or repair work can lead to issues with its operation.

Conclusion

In your trip to replace your generator starter pull rope or recoil spring, I hope this step-by-step advice has been useful. These abilities and expertise will enable future trouble-free starts and dependable power generation.

We appreciate you being a part of our DIY generator pull cord replacement adventure, and we wish you many trouble-free starts with your newly installed pull cord.

FAQs

Can I Replace the Pull Cord Myself, or Hire a Professional?

You can replace the pull cord yourself if you have some basic mechanical skills and the necessary tools. However, It is advised to engage a professional expert to perform the replacement if you are uncomfortable performing DIY repairs to prevent any possible damage.

What Size and Type of Pull Cord Should I Use For My Generator?

General size 2.5 fits portable generators. However, refer to your generator manual for the recommended pull cord specifications, including size and type, to ensure proper function.

How Often Should I Replace the Pull Cord On My Generator?

It’s recommended to replace the generator pull cord every 6 to 12 months, but overall, it depends on usage and wear.

My generator pull cord is stuck. What should I do?

If the pull cord is stuck, it may be due to a jam or mechanical issue. It is advisable to think about looking for local professional repair help.

Do I Need to Take any Safety Precautions When Changing the Pull Cord?

Yes, always disconnect the spark plug wire and ensure the generator is off before attempting any pull cord replacement. Wear safety gear like gloves and eye protection to prevent injury.